The carbon electrode is generally used for calcium carbide and industrial silicon smelting, due to the large diameter of the electrode and the high current carrying density, the large-size carbon electrode is gradually transferred to the low-ash and low-sulfur petroleum coke as raw materials to produce large-size graphite electrodes for industrial silicon and calcium carbide smelting.

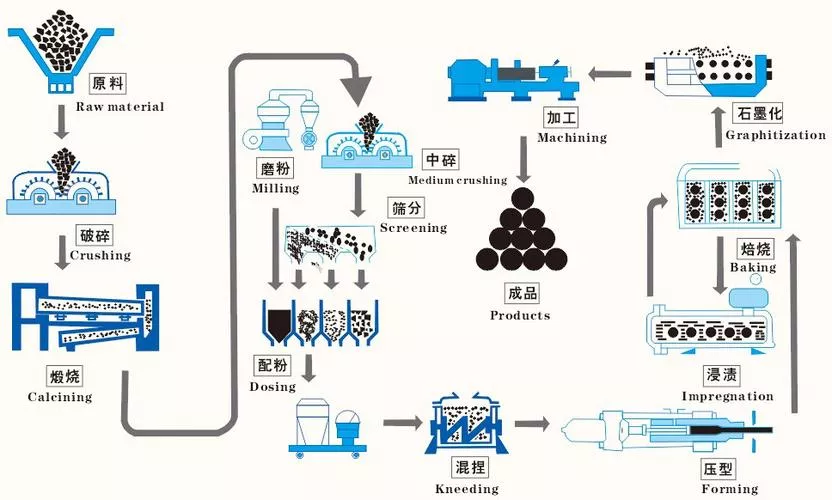

Carbon electrode is a new type of energy saving and environmental protection material,which is made of electrically calcined anthracite,petroleum coke,crushed graphite and coal pitch as the main raw materials,and is widely used in industrial silicon,ferroalloy,calcium carbide,yellow phosphorus and other metals or non-metal smelting process.Carbon electrode is energy saving and environmental protection products,which can greatly reduce the smelting power consumption and reduce pollution when used in calcium carbide and ferroalloy ore heating furnace.

At present,industrial silicon and yellow phosphorus smelting furnaces have begun to replace the higher price of graphite electrodes.In the same capacity of submerged arc ore furnace,compared with the graphite electrode,the diameter of the carbon electrode can be made larger(Φ650-Φ1272mm carbon electrode can be produced in China,and the graphite electrode can beΦ1146mm in China),so that the arc zone in the furnace is widened,the arc is stable,and the hot melt efficiency is ensured,the product output is increased,and the product power consumption is reduced.

Type of furnace used:Electric calciner,Calciner,Ring pit baking furnace,Graphitization furnace