The cathode carbon block is divided into semi-graphitic aluminum cathode, high graphitic aluminum cathode and graphitized cathode.

Aluminum cathode is generally made of high-quality anthracite,coke,graphite and other raw materials,according to the use of different parts are divided into bottom carbon block,side carbon block,carbon paste or carbon glue to connect the carbon block and cathode steel rod.

1.Bottom carbon block.It plays the dual role of conducting electricity and forming the lining of the electrolytic cell.It is masonry at the bottom of the electrolytic cell,and the external masonry refractory material is reinforced with steel shell.It can be divided into ordinary cathode carbon block,semi-graphite cathode carbon block and graphite cathode carbon block.

2.Side carbon block.It is used for masonry the side of the aluminum electrolytic cell and forming the main lining of the side of the electrolytic cell.It can be divided into ordinary side carbon block and semi-graphitic side carbon block,and the production method is similar to the bottom carbon block.With the popularization of silicon nitride combined with carbonized silicon block in the side of aluminum electrolytic cell,the amount of side carbon block has decreased.

3.Cathode steel rod.The product connecting the cathode carbon block and the cathode bus in the aluminum electrolytic cell is the cathode circuit composition of the aluminum electrolytic cell.It is divided into single rod(that is,a cathode steel rod is assembled on a cathode carbon block)and double rod(that is,two cathode steel rods are assembled at the both end of a cathode carbon block).

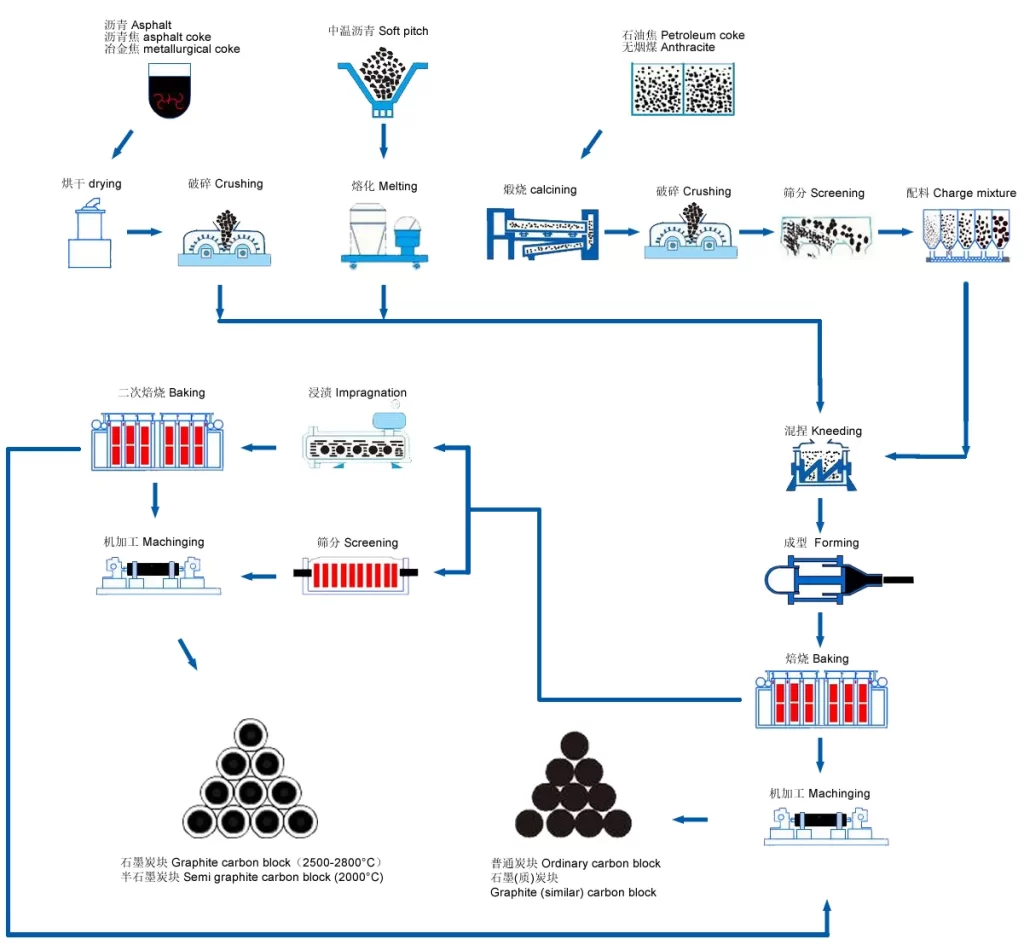

The raw materials of the cathode carbon block are mainly anthracite,pitch coke,artificial graphite and coal pitch,etc.The raw materials are calcined,broken and screened into a certain grade,measured according to the formula,and then added to the binder for kneading.The finished cathode paste is finished after kneading,then become cathode carbon block by forming,baking,graphitizing and machining.

Cathode carbon block production process:

Type of furnace used:Electric calciner,Ring pit baking furnace,Graphitization furnace