Petroleum Coke Classification and use:

Petroleum coke is classified into low ash and low sulfur petroleum coke,medium sulfur petroleum coke and high sulfur petroleum coke according to sulfur content and ash content.

Petroleum coke can be divided into delayed coke,kettle coke,fluid coke and open furnace coke according to different refining processes.

According to the different forms of petroleum coke can be divided into:needle coke,shot coke or ball coke,sponge coke,powder coke four kinds.

Petroleum coke can be divided into sponge coke and needle coke according to the different microstructure and morphology.The former is porous and spongy,also known as ordinary coke;The latter is dense and fibrous,also known as high-quality coke.

High quality low sulfur and low ash calcined petroleum coke,such as needle coke,is mainly used in the manufacture of ultra-high power graphite electrodes and some special

carbon products;In steelmaking industry,ultra-high power graphite electrode is an important material for developing new technology of EAF steelmaking.

Medium sulfur,common calcined coke,used in aluminum smelting in large quantities.

High sulfur,ordinary coke,is used for chemical production,such as the manufacture of calcium carbide,silicon carbide,etc.,but also as a fuel for glass,metal casting and so on.

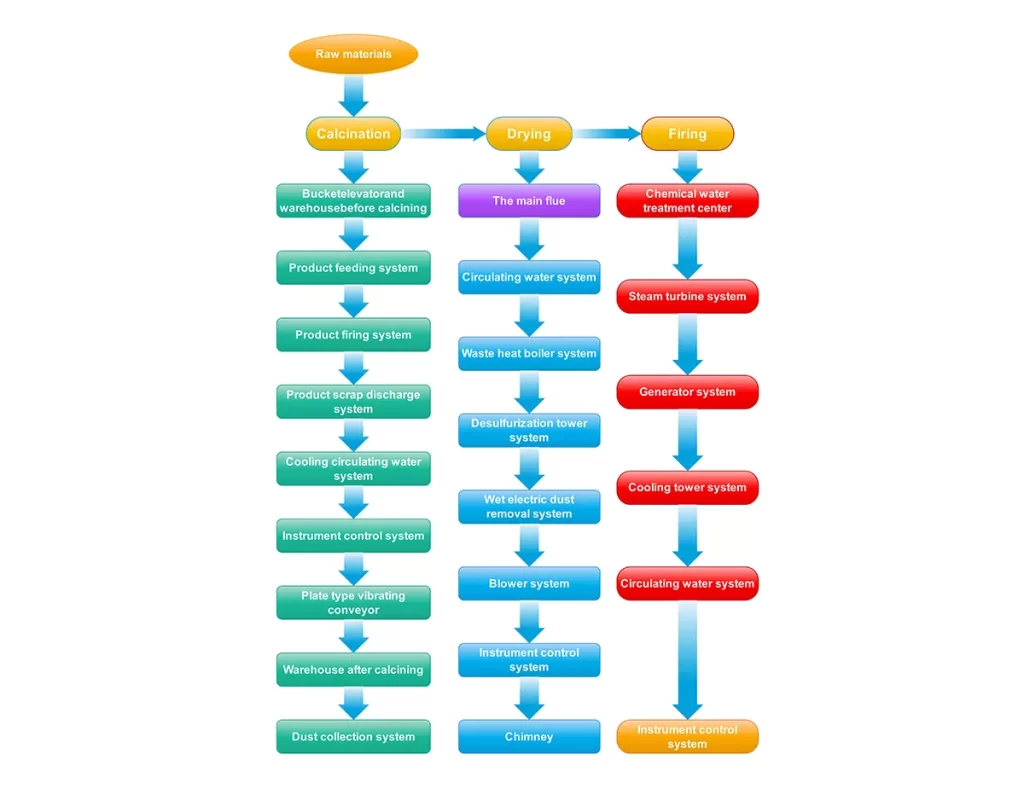

High temperature calcination technology of petroleum coke

Combined with the chemical industry to calcined petroleum coke quality,production safety,yield cost,investment intensity and other aspects of consideration,our company adopts tank calciner technology.

The main structure of the tank calciner is:tank,fire passage,heat exchange chamber,adding and discharging device,cooling water circulation device,etc.In the process of high temperature calcination,the volatiles discharged from the calcined materials are used to burn the hot calcined materials,so as to achieve the purpose of energy saving and consumption reduction.Common calcination tanks are divided into co-flow calcination and counter-flow calcination according to the air flow and flow direction.