Pre-baked anode is a kind of aluminum carbon, belongs to the supporting industry of aluminum industry, one of the main raw materials of electrolytic aluminum, according to relevant data statistics, electrolytic aluminum enterprises to produce 1 ton of electrolytic aluminum needs about 0.49~0.53 tons of pre-baked anode, is the current aluminum electrolytic process irreplaceable consumption material, is also an important consumable of aluminum smelting process. Pre-baked anode has good electrical conductivity and high temperature corrosion resistance, known as the "heart" of the electrolytic cell, so the anode quality directly affects the current efficiency of the electrolytic cell, anode consumption and primary aluminum quality.

Pre-baked anode is actually a comprehensive resource utilization product. The specific production process takes petroleum coke, a by-product of petrochemical industry, as the aggregate, and coal pitch, a by-product of coal chemical industry, as the binder. After mixing and forming, it forms a certain shape of green product. After heat treatment, the binder is carbonized to obtain high mechanical strength and oxidation resistance, so as to produce anode products with low resistivity.

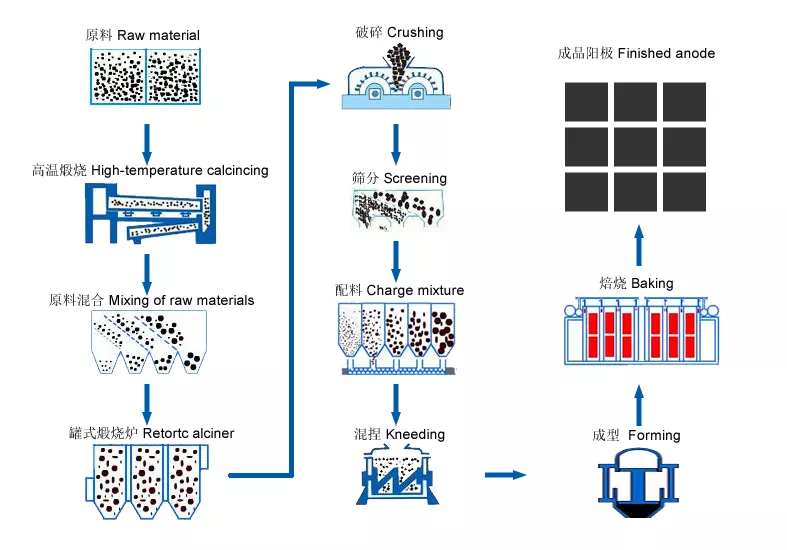

Pre-baked anode production process:

1.Raw materials.The pre-baked anode is made of less ash raw materials,petroleum coke and residue used as aggregate,the impurity content is generally not more than 0.5%,and the binder is coal pitch.Modified pitch or high temperature pitch has been widely used as binder for pre-baked anodizing.

2.Calcination.The petroleum coke was calcined by a tank calciner at a high temperature of about 1250 degrees.

3.Crushing and screening.The calcined petroleum coke and residue are broken,screened and grinding into different strength materials according to the formula requirements,and then loaded into their respective silos.

4.Batching.The batching are carried out according to the set formula,the formula of pre-baked anode has two kinds of large particle formula and small particle formula,the largest particle of aggregate is 12mm~15mm,the amount of coal pitch varies according to the dry material formula and forming process,generally 16%~18%.

5.kneading.The plasticity paste materials was made by kneading the aggregate and binder evenly with the intermittent horizontal double-axis kneading machine or continuous kneading machine.

6.Forming.The paste materials was prepared into pre-baked anode block under high frequency vibration by special vibration forming machine.

7.Baking.The baking heat treatment of pre-baked anodes is usually done by open type ring pit furnace.

8.Cleaning and processing.The pre-baked anode carbon block after baking is slightly cleaned and checked to be qualified before leaving the factory.

Type of furnace used: Calciner, Ring pit furnace